RIVETS AND RIVETED JOINTS

Riveted

joints:

In riveted joints were classified

as one of the types of permanent fastenings. They are generally used to fasten

metal plates and steel section in structural works such as bridge and roof

trusses and in the construction of pressure vessels such as storage tanks

boilers. The field of application of riveted joints has been considerably

reduced by the welded joints because of the simplified process of making the

welded joint comparative strength and economy. However riveted joints are very

effective in designs subjected to pronounced vibration loads where welded

joints are less reliable. Riveted joints may also be employed to connect metals

which are difficult to weld together and in the joints which permit no heating welded

due to possible tempering or warping of the finished machine parts.

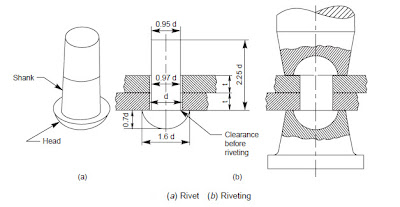

Rivet:

A rivet is a round rod of either mild steel or nonferrous

materials such as copper aluminum with a head of any one of the shapes formed

at one end during its manufacture and its tail end being slightly tapered as

the length of the shank of the rivet should accommodate the thickness of the

connecting plates and also provide sufficient material for forming the head at

the tail end in general the eight of shank of the rivet will be equal to sum of

the thickness of the connecting plates plus 105 to times the diameter of the rivet.

If

l = length of the shank of the rivet

d

= diameter of rivet

r

= thickness each of the connecting plates then

l

= ∑t + (1.5 to 1.7) d

Riveting:

Riveting is the process of forming a well shaped

concentric head from the project-ting tail end of the shank rivets inserted in

the holes previously drilled in the plates to be fastened, without allowing it

to develop an initial stress so that it can take up the designed working shear load.

The process of making the riveted joint involves making of the hole in the

plates and the formation of the head out of the projecting tail end of the

shank of the rivet.

Riveted joints must be made air tight in applications such as boilers and other pressure vessels.Caulking or fullering is done to make the riveted joints air tight.

Caulking:

The outer edges of the plates used in boiler and other pressure vessels are beveled To produce air tight riveted joints, these beveled edges of the plates are caulked. Caulking is an operation in which the outer bevel led edges of the plates are hammered and driven-in by a caulking tool.The caulking tool is in the form of a blunt edged chisel.

Fullering:

Similar to caulking, fullering is also used to produce air tight joints. Unlike the caulking tool, the width of the fullering tool is equal to the width of the beveled edges of the plates Caulking and fullering operations are carried out effectively by applying pneumatic pressure.

Lap Joint:

In a lap joint, the plates to be riveted, overlap each other. The plates to be joined are first beveled at the edges, to an angle of about 80° . Depending upon the number of rows of rivets used in the joint, lap joints are further classified as single riveted lap joint.

Butt Joint:

In a butt joint, the plates to be joined, butt against each other, with a cover plate or strap, either on one or both sides of the plates; the latter one being preferred. In this joint, the butting edges of the plates to be joined are square and the outer edges of the cover plate(s) is(are) beveled In a single strap butt joint, the thickness of the strap (cover plate) is given by, t1 = 1.125t If two straps are used, the thickness of each cover plate is given by, t2 = 0.75t.

Emperical

proportions of Rivet joints:

For

the given thickness of the connecting plates the other dimensions such as rivet

diameter pitch the distance from the centre of the rivet to the edge of the

plate transverse pitch thickness of the cover plates in case of butt joints that

are required to make the riveted joints are obtained from the Emperical

proportions. For general use the Emperical proportions given in the may be

used. In the design of the boiler joints the Emperical proportions specified by

the Indian boiler regulations.

Emperical

proportions for general use:

The

following Emperical proportions may be used for riveted joints in general class

of work.

Diameter

of rivet: d = 6√ t mm

Where t = thickness of the

connecting plates in mm

Longitudinal

pitch: p =3d

Center

of the rivet to the edge of the plates = 1.5 d

Transverse

pitch: pt = 0.6 p…. For zig-zag riveting

Pt = 0.8 p…. For chain riveting

Thickness

of cover plates or butt straps:

Thickness of single cover

plate t₁ = 1.125 t

Thickness of double cover

plate t₂ = 0.7 t to 0.8 t.

Emperical

proportions for Boiler joints:

In the design of riveted joints for boiler work the

following Emperical proportions as specified by the Indian boiler regulation

known as I.B.R. should be used.

Lap joints:

Diameter of rivet: d = 6√ t mm

Where t = thickness of

the connecting plates in mm

Longitudinal pitch p:

p = 2t + 4lmm ….. For single riveted

p = 2t + 4lmm ….. For double riveted

p = 2t + 4lmm ….. For treble riveted

p = 2t + 4lmm ….. For quadraple riveted

Center

of the rivet to the edge of the plates = 1.5 d

Transverse

pitch pt:

Pt = 2d…. For chain

riveting

Pt = 0.33 p +0.67d …. For zig-zag

riveting

Boiler joints:

Diameter of rivet: d = 6√ t mm

Where t = thickness of

the connecting plates in mm

Longitudinal pitch p:

p = 1.53t + 4lmm ….. For

single riveted and single strap

p = 3.06t + 4lmm ….. For double

riveted and single strap

p = 4.05t + 4lmm ….. For treble

riveted and single strap

p = 1.75t + 4lmm ….. For

single riveted and double strap

p = 3.5t + 4lmm ….. For double

riveted and double strap

p = 4.63t + 4lmm ….. For treble

riveted and double strap

p = 5.52t + 4lmm ….. For quadraple

riveted and double strap

Center

of the rivet to the edge of the plates = 1.5 d

Transverse

pitch pt:

Pt = 2d…. For chain

riveting

Pt = 0.33 p +0.67d …. For zig-zag

riveting

Thickness

of cover plates or butt straps:

Thickness of single cover

plate t₁ = 1.125 t

Thickness of double cover

plate t₂ = 0.625t.

I have read this blog very useful information about Rivet joints..Thanks

ReplyDeletehttp://www.ushaprecision.com/